Watch Repair Basics

[Pocket Watch Dials] [Watch Jewels] [Escapement] [Care of your Vintage Watch]

Adjustment

Movements that are marked to be “adjusted” may have a variety or combination of features. One has to read the catalog description for any given movement grade to discover just what level of adjustment is being claimed. High grade watches built after 1905-1908 may be marked with specific adjustments.

This is especially true for watches intended for use in railroad time service. The balance, the wheel that spins back and forth rapidly, is the device that sets the timekeeping rate of the watch. The purpose of all of the features for an adjusted watch is to keep the balance (wheel), as nearly as possible, oscillating at a consistent rate. The consistency of the rate of oscillation of the balance (wheel) determines the timekeeping quality of the watch.

Temperature Compensated Balance (Wheel)

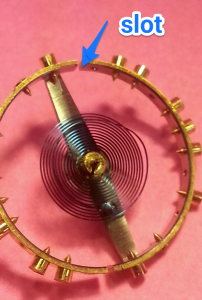

A balance (wheel) that is temperature-compensated has the rim made of two dissimilar metals. There are usually two arms (spokes) from the hub supporting the rim and there is a slot cut in the rim just past each arm. This forms two rim segments having one end supported by the arm and the far end free to move. These slots, and the two colors of metal in the rim, are identifying characteristics.

As the temperature increases, lessening the power of the hairspring – the spring coiled inside of the balance (wheel) – the far ends of the rim segments deflect inward. As temperature decreases, the segment ends relax, moving outward, as the hairspring strength increases. The action is much like an inexpensive thermostat in the home. This movement of the rim segments changes the moment of inertia of the balance (wheel), compensating for the alteration in the hairspring strength.

Adjustment to Temperature

This is sometimes referred to as adjustment to heat and cold. It requires a temperature compensated balance. The balance has pairs of screws (180 degrees apart) set into the rim. These give the balance mass, which sets the basic rate at which it oscillates.

One pair may be the meantime screws (which can be identified – if present – by being longer than the other screws), used to bring the rate deviation to minimum (with its regulatory center position) after all of the other adjustments have been made.

The locations of most of the pairs of screws (each pair is 180 degrees apart) on the balance (wheel) rim are chosen to provide the best match of change in moment of inertia to change in hairspring strength (there are extra pairs of holes so that the screws may be moved to the best possible positions). The object is to keep the balance (wheel) oscillating at the same rate over the specified temperature range.

Adjustment to Position

The next level is adjustment to position. This is adjustment to maintain the same rate of balance (wheel) oscillation, regardless of which of the specified positions the watch is in. There are a total of six positions. Unfortunately, the number or the positions to which the watch is adjusted isn’t specified for most watches built prior to 1905-1908. Typically, unspecified adjustment to position means adjustment to three positions, but there are a number of instances in which it means five, or sometimes 6, positions. Adjustment to three positions most likely means stem up, stem at the 3 o’clock position and stem at the 9 o’clock position.

Some watches are marked “8 Adjustments.” Depending upon the manufacturers specification at the moment that the watch was made, this can mean adjustment to temperature, isochronism (see below) and 6 positions. Or, it may mean adjustment to heat, cold, isochronism and 5 positions. To clear up the ambiguity, in the early 1950’s, Elgin marked its top (and only) railroad pocket watch “9 Adjustments.”

The marking “Adjusted” on a movement means whatever the manufacturer said it meant at the time that the watch was built. Lacking descriptive factory literature, we have no way of knowing what that means today. Unless a watch is specifically marked as to the number of positions to which it is adjusted, such as a watch that is only marked “Adjusted.” The only way to know that number (if it is adjusted to positions at all) would be to identify the grade and find the manufacturer’s description of the position adjustment for that grade.

Adjustment to Isochronism

Adjustment to isochronism is accomplished by the design and adjustment of the hairspring – the spring coiled inside of the balance (wheel). The power output of the mainspring (the spring that is wound when winding a watch) tends to decrease as it unwinds over the course of the day. This causes the balance (wheel) to rotate through a greater rotational angle when the mainspring is just wound and a lesser angle when the mainspring needs winding.

A watch adjusted to isochronism oscillates the balance (wheel) at the same rate throughout the specified length of run between windings of the mainspring, regardless of how far in each direction the balance (wheel) rotates.

This length of run is typically 30 hours for earlier watches and 42 hours for post World War I watches of better quality. However, mainsprings whose power output were nearly constant over the first 20 hours after a full winding were supplied in higher grade watches starting in the late 1920’s. The need for adjustment to isochronism lessened with the application of these mainsprings.